Brand Name: Yongda

Model Number: WZP-200

Place of Origin: Henan, China (Mainland)

After-sales Service Provided: Engineers available to service machinery overseas

subject: ultrasonic frequency induction heating machine

usage: heating metal,forging/hardening/brazing etc.

Input current: 6-200A

Oscillation frequency: 15-30 KHZ (Customized)

Core parts: IGBT modules

Cooling method: Water cooling machine

coils material: copper tube

generator size: 850*600*1330mm

transformer size: 780*540*520mm

warranty: one year free replacment spare parts

High quality IGBT modules ultrasonic frequency induction heating machine

Technical parameters of ultrasonic frequency induction heating machine

Model |

Input voltage |

Input current |

Oscillation frequency |

Cooling water pressure |

WZP-40 |

320-420V |

2-40A |

15-30KHZ |

0.1MPA |

WZP-60 |

320-420V |

3-60A |

15-30KHZ |

0.2MPA |

WZP-90 |

320-420V |

4-90A |

15-30KHZ |

0.3MPA |

WZP-120 |

320-420V |

6-120A |

15-30KHZ |

0.3MPA |

WZP-160 |

320-420V |

6-160A |

15-30KHZ |

0.3MPA |

WZP-200 |

320-420V |

6-200A |

15-30KHZ |

0.3MPA |

WZP-300 |

320-420V |

6-300A |

15-30KHZ |

0.3MPA |

WZP-400 |

320-420V |

6-400A |

8-15KHZ |

0.3MPA |

WZP-500 |

320-420V |

6-500A |

8-15KHZ |

0.3MPA |

Features of ultrasonic frequency induction heating machine.

1.High efficient: energy saving,environmental protection

2.Heating fast:The fastest heating speed is less than 1 second

3.Heating wide: can heating variety of metal workpieces(according to different shapes of work pieces, replace removable induction coils)

4.Easy installation :the machine can be used,as soon as connected the power supply, induction coils, water inlet and outlet.

Small size, light weight ,easy to use

5. Simple operation , several minutes to learn.

6. Start fast, pass water and electric power can start heating

7.Low power consumption:can save about 40% energy than tradional HF tube furnace , save degree is relation with shpes of work pieces and induction coils.

8.Good effect: Heating very uniform (by adjusting the density of induction coils, makes every parts of work piece obtain the respective needs of temperature), warming up fast, less oxidation layer, surface got good gloss after heating .

9.Full protection: has over voltage,over current,temperature is over high,lack of water, lack of phase,etc, alarm lamps indicators. can automaticly control and protection the machine itself.

10.Temperature is adjustable, by setting heating time and the infrared thermometer, to control heating temperature of work pieces.Thus control heating temperature to a technology points , Can also increase the insulation function.

11.High security, eliminating the nearly million-Volt high voltage

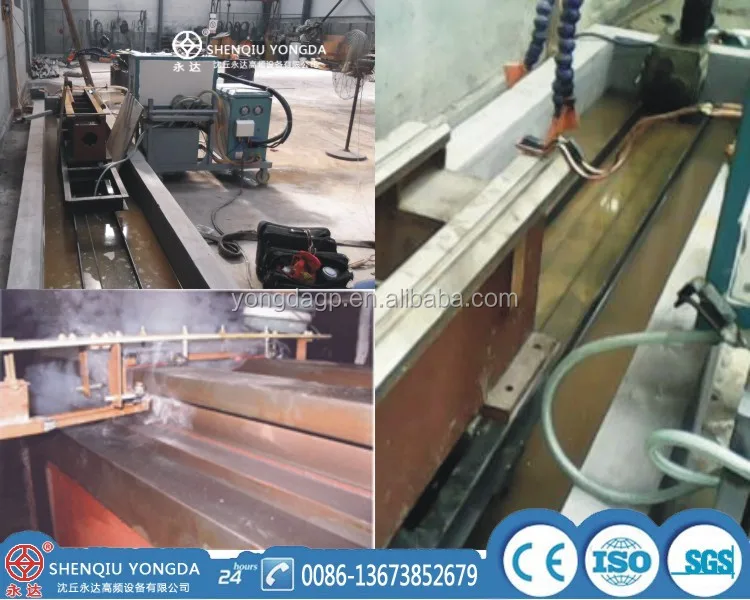

Photos of ultrasonic frequency induction heating machine. ISO9001:2000 Certifications

Applications of ultrasonic frequency induction heating machine

1, Induction forging

A, all kinds of standard parts, fasteners, machinery parts, hardware tools, straight shank twist hot upsetting, hot.

B, metal heat annealing. Such as: tensile steel tube, pipe, smashed head; wire, heating wire nail; stainless steel annealed, rose type.

Standard parts hot forging

2, Induction hardening

Various types of hardware, electrical, hydraulic, pneumatic components, automobiles, and motorcycle parts and other mechanical parts of the surface of the metal, bore, in part or in whole quenching. Such as: hammer, knife, scissors, pliers and various types of shafts, cams, sprockets, gears, valves, ball pin, large-scale Machine Tool, ductile iron quenching.

Machine tool guide rail hardening

3, Induction brazing

Various types of carbide blades, turning, milling, planer, reamer, diamond saw blade, saw welding; grinding, drilling, cutting welding; brass, copper, stainless steel and other metal materials, the composite bottom of the pot Welding.

4, metal melting: melting gold, silver and copper.

5, the other heated areas

Plastic pipe, cable, wire heating film; food, beverage, pharmaceutical industry uses aluminum foil.

Oversea customers visit us .

Packing for ultrasonic frequency induction heating machine

1.Wooden cases (plywood) or carton, as you required.

2.Inside,will be filled with plastic foam,for waterproof and shockproof.

3.Accessories: induction coils,foot switch and installing and operating instructions

Shipping: by sea LCL(less than container load) or by air/train/courier

Thanks for your reading,if you are interested in induction heating machine, welcome to contact Jessie at any time !