Brand Name: Yongda

Model Number: IGBT-300KW

Place of Origin: Henan, China (Mainland)

Condition: New

Type: Induction Furnace

Usage: Heat Treatment Furnace

Voltage: 320-420V, 3 phase 380V or 440V

Power(W): 300KW

Certification: CE ISO

Warranty: one year

After-sales Service Provided: Engineers available to service machinery overseas

name: induction heating furnace

usage: heating steel , iron, brass, Aluminium etc. metal parts

Oscillation frequency: 2-10 KHZ

Core parts: IGBT modules

Alarm Functions: OV,OC,LW,LP etc.indicators

nature of us: 20 years manufacturer

export market: Europe, Asia, South America, Oceania etc.

Packing: standard export wooden cases

Yongda new technology induction heating furnace

IGBT Medium Frequency induction heating furnace is a static frequency conversion devices, use IGBT element, convert power frequency three-phase AC power into an intermediate frequency single-phase AC power supply. Mainly used in induction heating, induction melting and other needs of intermediate frequency power supply applications. Because of its overall high efficiency, light weight, low noise, start and stop quickly and without impact on the power grid, frequency automatic tracking load parameters change, convenient power adjustment etc. a series of advantages, it is gradually replacing the intermediate frequency generators, SCR/KGPS MF devices.

The device main circuit adopts "AC - DC - AC" conversion system consists of a three-phase full-controlled bridge uncontrolled rectifier circuit, a capacitor filter circuit, a series inverter circuit .IGBT, rectifier bridge etc. element is water cooled. Its control system consists of an integrated circuit, stable performance, reliable. Start using advanced scanning start, zero current turn mode, safe and convenient, easy maintenance, economical, especially for metal smelting, heating and heat treatment conditions.

Techncial specifications of induction heating furnace

item |

Model |

MF frequency KHz |

MF power kW |

MAX. DC current A |

1 |

IGBT-25 |

1-500 |

25 |

50 |

2 |

IGBT-50 |

1-500 |

50 |

100 |

3 |

IGBT-100 |

1-300 |

100 |

200 |

4 |

IGBT-160 |

1-100 |

160 |

320 |

5 |

IGBT-250 |

1-100 |

250 |

500 |

6 |

IGBT-300 |

1-50 |

300 |

600 |

7 |

IGBT-500 |

1-50 |

500 |

1000 |

8 |

IGBT-1000 |

1-30 |

1000 |

2000 |

9 |

IGBT-1250 |

0.5-10 |

1250 |

1400 |

10 |

IGBT-1500 |

0.5-10 |

1500 |

1600 |

11 |

IGBT-2000 |

0.5-10 |

2000 |

2200 |

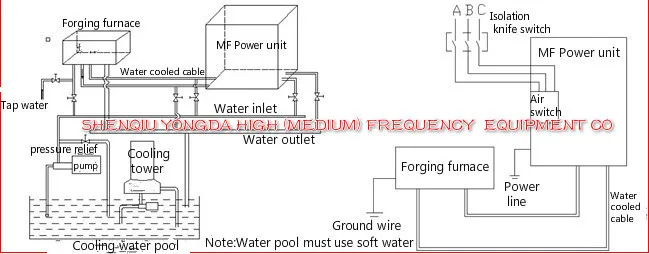

Composition of medium frequency induction heating furnace

Induction heating furnace can be used for heating the following work pieces

(1) Round steel categories:

A. bolts, nuts, drill head hot forge, the car U-bolts, anchor bolt, connecting rod, non-standard parts processing, conductive rod

B. stainless steel tableware, stainless steel bolts and nuts

C. tools: pliers, bolt cutters, pipe clamp, water pump pliers, pliers, wrenches, ratchet wrenches, masonry chisel,

D. Other: sewing gadgets, jack head, boss chair, shackles, hand rings, flowers Lancashire body, feet kidnapper, tricycle axle, briquettes machine Chong-pin, roll gate axis, articulated manifolds, hot-rolled twist drill, Hot-rolled rebar, hot-rolled woodworking drill, bearing

(2) sheet/plate categories:

A. forged stainless steel cutlery, automotive steel plate.

B. sheet folding: folding iron hand jack, metal folding channel, automotive steel, hot rolled construction steel buckle, automotive leaf spring

C. embossed: Iron Works embossing, embossing motorcycle brake pedal heating, sanitary ware.

D. Forming: bending, upsetting head, punching, flatten, step by step tight angle iron molding, from nails, rasp, sanitary ware

Induction heating furnace for forging steel

Control panel of IGBT medium frequency control cabinet

Pre-sale service:

We will recommend the most applicable equipment for customers according to your work piece processing demands.

In-sale service:

(1) We will strictly produce the equipment according to relevant technical standards.

(2) We will take run test according to relevant equipment test run regulations.

(3) We will strictly inspect the equipment before delivery,only good machine will be sent to customers.

(4) We will send goods as scheduled in the contract.

After-sale service:

(1) We will freely guide installation, commissioning and test run,by sending intall drawings, sometimes calling or send email.

(2) We will execute one-year guarantee period (ex. not include normal wear, damages of wearing parts and parts damages caused by improper operation).

(3) Once there is a trouble during quality guarantee period, our company promises that we will promptly appoint engineer and sales to help, make our efforts to remove troubles and guarantee the normal operation of customers.

(4) We will freely replace all equipment parts during guarantee period. After-sale products archives and life-long repair solve the potential problems of customers.

(5) Provide long-terms technical support. Also for different work pieces , give instructions and help about how to produce inductors.

(6) According to customer’s need, can arrange engineer to install ,test machine and training operators.

(7) After guarantee period, customer can buy machine parts from us with very low cost.

Sincerely provide service for you!